|

Getting your Trinity Audio player ready... |

Understanding the Pitot Tubes and Insertion Flow Meter: Principle, Construction, and Working

Pitot tubes: he Pitot tube is a widely used instrument in fluid mechanics to measure the velocity or flow rate of liquids and gases in a given system. It is primarily used to determine the speed or velocity head of a fluid by measuring the pressure difference at a single point of flow. In addition to its fluid flow measurement capabilities, the Pitot tube is often referred to as an insertion flow meter due to its design and method of installation. This article will explain the principle, construction, working mechanism, and applications of the Pitot tube, along with its advantages and disadvantages.

What is a Pitot Tube?

A Pitot tube is a simple device used to measure the flow velocity of a fluid. It is a type of differential pressure measuring device, based on the principles of Bernoulli’s theorem. This instrument works by measuring the difference in pressure between two points in the flow—one point facing the direction of the fluid flow (measuring dynamic pressure) and another perpendicular to the flow (measuring static pressure).

This difference in pressure, when combined with the known dimensions of the pipe and the fluid properties, can be used to calculate the flow velocity at the point where the Pitot tube is inserted. It is commonly used in industrial and scientific applications to gauge airspeed, water speed, or the velocity of other gases and liquids.

Principle of the Pitot Tube

The Pitot tube operates on the principle of Bernoulli’s theorem, which states that in a streamline flow of an incompressible fluid, the total mechanical energy (pressure energy, kinetic energy, and potential energy) remains constant. The fluid’s velocity at any point in the pipe can be determined by measuring the pressure difference between two points—one at the point of insertion (dynamic pressure) and another at right angles to the flow (static pressure).

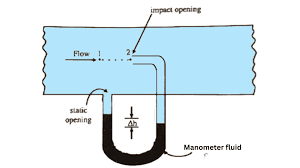

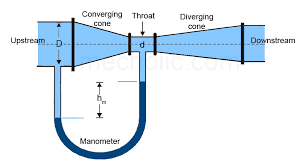

The Pitot tube has two key components:

- The static pressure tube: This tube is placed perpendicular to the direction of fluid flow and measures the static pressure.

- The dynamic pressure tube: This tube faces directly into the flow, capturing both the static pressure and the kinetic energy (or dynamic pressure) associated with the flow.

The difference in the pressure readings (called the velocity head) between these two tubes allows for the calculation of the flow velocity at the point of insertion.

Construction of the Pitot Tube

The construction of a Pitot tube is relatively simple but precise in its design. Here are the main components:

- Insertion into the Flow: The Pitot tube is usually inserted into the fluid flow, with its orientation carefully controlled. It is small compared to the diameter of the pipe it is measuring and is designed to minimize disruption to the flow.

- Two Tubes:

- One tube faces directly into the flow (the dynamic pressure tube).

- The other tube is placed perpendicular to the flow direction (the static pressure tube). This allows the measurement of static pressure without interference from the fluid’s velocity.

- Manometer: A manometer is attached to the Pitot tube to measure the pressure difference (ΔH) between the dynamic and static tubes. The manometer provides the reading of the velocity head, which is used to calculate the flow rate.

The overall design of the Pitot tube allows it to be inserted into the pipe or duct, making it an ideal insertion flow meter for measuring fluid velocities in a variety of settings.

Working Mechanism of the Pitot Tube

The Pitot tube works by measuring the pressure head difference between two points in the fluid flow. Here is a step-by-step explanation of how it functions:

- Insertion of the Tubes: The two tubes of the Pitot device are inserted into the pipe or duct through which the fluid is flowing. The dynamic pressure tube is oriented in line with the flow, while the static pressure tube is placed perpendicular to the flow.

- Pressure Measurements:

- The static pressure tube measures the pressure of the fluid at rest or the pressure exerted by the fluid that is not moving in the direction of the flow.

- The dynamic pressure tube measures the pressure at the point of insertion, which includes both the static pressure and the pressure due to the fluid’s velocity (kinetic energy).

- Pressure Head Difference (ΔH): The difference in pressure between the two tubes—dynamic and static—measures the velocity head. This difference is usually displayed on a manometer connected to the tubes.

- Velocity Head Calculation: Using the following formula based on Bernoulli’s theorem, the velocity of the fluid can be calculated:

V=Cv2⋅g⋅ΔHV = C_v \sqrt{2 \cdot g \cdot \Delta H}V=Cv2⋅g⋅ΔH

Where:

- VVV = Velocity of the fluid (velocity head)

- CvC_vCv = Coefficient of the Pitot tube

- ggg = Gravitational constant (9.81 m/s²)

- ΔH\Delta HΔH = Pressure head difference (measured by the manometer)

This equation allows the user to calculate the flow velocity at the point where the Pitot tube is inserted.

- Average Flow Velocity: Although the Pitot tube measures the velocity at one specific point, the average velocity across the entire cross-section of the pipe can be obtained by moving the Pitot tube to various points within the flow. An adjustable Pitot tube may be used to take readings from different points across the pipe’s cross-section to calculate the average flow rate.

Types of Pitot Tubes

Pitot tubes can be classified into two major types:

- Standard Pitot Tube: This is the basic type of Pitot tube that consists of a simple setup with one static pressure port and one dynamic pressure port. It is typically used for low-pressure systems.

- Averaging Pitot Tube: This type of Pitot tube includes several pressure ports along its length to take multiple pressure readings across the pipe’s diameter. The averaged pressure measurements are then used to calculate a more accurate average flow rate across the cross-section of the pipe.

Applications of Pitot Tubes

Pitot tubes have a wide range of applications in various industries, including:

- Aviation: Pitot tubes are most famously used in aircraft to measure the airspeed of an aircraft. They are a crucial component of the airspeed indicator in aircraft, helping pilots understand the speed of the aircraft relative to the surrounding air.

- Industrial Fluid Flow Measurement: In industries such as chemical, oil, and water treatment, Pitot tubes are used to measure the velocity of fluid flow in pipes and ducts, helping to monitor and control industrial processes.

- Marine: Pitot tubes are used on boats and ships to measure the speed of the vessel in water.

- HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, Pitot tubes are used to measure the airflow velocity in ducts and pipes.

Advantages of Pitot Tubes

- Cost-Effective: Pitot tubes are inexpensive compared to other types of flow meters.

- Simple Design: The design of a Pitot tube is relatively simple, which makes it easy to install, maintain, and use.

- No Moving Parts: Since the Pitot tube has no moving parts, it has low maintenance requirements and a long lifespan.

- Versatile: Pitot tubes can be used to measure both gas and liquid flow velocities.

Disadvantages of Pitot Tubes

- Limited to Single Point Measurement: A Pitot tube measures the velocity only at the point of insertion, which means it may not provide an accurate measure of the average velocity across the entire cross-section of the pipe unless multiple readings are taken.

- Disturbance to Flow: The insertion of the Pitot tube into the flow can create disturbances that may affect the accuracy of the measurement.

- Not Suitable for Low-Pressure Gas Flow: For gases under low pressure, the readings may be very small and require the use of additional multipliers or specialized gauges to accurately measure the flow.

- Requires Straight Pipe Sections: The Pitot tube needs to be inserted into straight sections of pipe to avoid flow disturbances caused by bends or fittings.

Conclusion

The Pitot tube is an essential and cost-effective tool for measuring fluid flow velocities in various industries. It operates on the principle of Bernoulli’s theorem, providing accurate measurements of dynamic and static pressure differences to calculate flow velocity. Although it has some limitations, such as measuring only at a specific point and creating flow disturbances, its simplicity, affordability, and ease of use make it an indispensable instrument for fluid flow measurement.

FAQs

Q: What is the primary function of a Pitot tube? A: The primary function of a Pitot tube is to measure the flow velocity (or speed) of a fluid by capturing the pressure difference between dynamic and static pressures in the flow.

Q: Can a Pitot tube measure both liquids and gases? A: Yes, Pitot tubes can be used to measure both liquid and gas flow velocities. However, they are more commonly used for gas measurements and may require modifications for low-pressure gases.

Q: What is the accuracy of a Pitot tube? A: The accuracy of a Pitot tube depends on the application, the fluid being measured, and the method used to take readings. Generally, Pitot tubes provide accurate measurements within a small range, but they require proper installation and alignment to minimize errors.

Leave a Reply