|

Getting your Trinity Audio player ready... |

Solid Dosage Forms: Tablets, Their Types, and Quality Control Tests

Introduction to Tablets in Pharmaceuticals

Solid Dosage Forms: Tablets are among the most widely used solid dosage forms in the pharmaceutical industry, produced for the purpose of delivering medications to patients in a controlled and efficient manner. These solid dosage forms are designed to hold one or more active pharmaceutical ingredients (APIs) and can be taken orally, making them part of a category commonly referred to as solid oral dosage forms. Tablets are available in various forms, such as plain, coated, or modified release, to accommodate different drug delivery needs and patient preferences.

The manufacturing process of tablets typically involves two methods: molding or compression. Molding is used primarily for effervescent tablets or those requiring special formulations, while the compression method is more commonly used for the majority of tablets available on the market. Other solid dosage forms also include capsules, powders, and sachets, each serving a different purpose but all sharing the same goal of efficient drug delivery.

What are Tablets?

Tablets are defined as solid, unit dosage forms designed to contain one or more active ingredients and are meant to be administered orally. The tablets themselves are composed of both the active pharmaceutical ingredients and various excipients. Excipients are inactive substances that serve several roles, such as binders, fillers, disintegrants, lubricants, and stabilizers. These components help ensure that the tablet holds together, is easy to swallow, and releases its active ingredients at the proper time and location in the body.

These solid oral dosage forms are designed for oral administration, meaning they are typically ingested with liquids like water, milk, or juice, although some tablets are designed to be chewed, dissolved in water, or dispersed before ingestion. Some specialized tablets may even be retained in the mouth for a slower release of the active ingredients.

Ingredients Used in Tablet Formulations

In addition to the active pharmaceutical ingredients, tablets also contain excipients. These excipients include:

- Binders: Help hold the tablet ingredients together, ensuring that the tablet does not disintegrate prematurely.

- Diluent or Filler: These substances add bulk to the tablet, making it the correct size and weight for administration. Common examples include lactose, cellulose, or starch.

- Disintegrants: These substances aid in the tablet’s disintegration once it enters the gastrointestinal tract, ensuring that the active ingredients are released effectively.

- Lubricants and Glidants: These ingredients help in the smooth manufacturing process and prevent the tablets from sticking to machinery.

- Coating Agents: Tablets may be coated for protection or to control the release of the active ingredient.

Tablets are often designed to be swallowed whole, although some are formulated for other purposes, such as dissolving in water or releasing their active ingredients in the mouth. Other solid dosage forms like pessaries or implants, which are administered via routes other than oral, may also be presented in tablet form but require specific formulation approaches.

Key Properties of Tablets

Tablets must meet specific properties and characteristics to be effective and safe for patient use:

- Durability: Tablets must be able to withstand the physical and mechanical stresses encountered during manufacturing, packing, shipping, and dispensing.

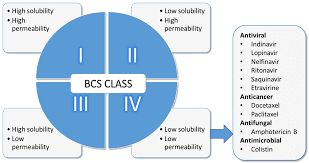

- Bioavailability: The active ingredients in the tablet must be bioavailable, meaning they are capable of being absorbed into the bloodstream after being released in the gastrointestinal tract.

- Uniformity: Tablets must be uniform in weight and drug content to ensure that each dose delivers a precise amount of active ingredient.

Types of Tablets

Tablets come in various types, each designed for a specific purpose based on the drug’s release profile or patient preference. The different types of tablets include:

- Core Tablets or Uncoated Tablets Core tablets are the simplest form of tablets. They consist of a single compressed layer of active pharmaceutical ingredients combined with excipients. These tablets are typically designed to disintegrate rapidly in the stomach, allowing for quick drug release.

- Coated Tablets Coated tablets are designed to protect the tablet or control the release of the active ingredient. There are two main categories:

- Film-Coated Tablets: These tablets are coated with a thin layer of polymers such as hydroxypropyl methylcellulose. The coating helps protect the active ingredient and can also control the release of the drug.

- Sugar-Coated Tablets: These tablets are coated with a sugary layer to improve taste, mask unpleasant odors, and protect the drug from moisture or light. The process of sugar-coating involves several stages, including sealing, subcoating, coloring, and polishing.

- Enteric-Coated Tablets Enteric-coated tablets are designed to resist dissolution in the acidic environment of the stomach, with the intention of releasing the drug in the more neutral or alkaline environment of the small intestine. This is particularly useful for drugs that may be irritating to the stomach or that are absorbed better in the intestine.

- Dispersible Tablets These tablets are designed to disperse in water, forming a suspension of the active ingredient. They are typically uncoated and may include flavoring and coloring agents to improve palatability.

- Modified Release Tablets Modified release tablets are designed to release the drug over an extended period, helping to maintain therapeutic drug levels over a longer time. There are several variations, including:

- Prolonged Release Tablets: These tablets release their active ingredients slowly over time, providing continuous therapeutic effects.

- Effervescent Tablets: These tablets contain acidic substances that react with a base when they come into contact with water, releasing carbon dioxide and helping the drug to dissolve or disperse.

- Lozenges and Sublingual Tablets Lozenges are designed to dissolve slowly in the mouth, releasing their active ingredients gradually. Sublingual tablets are placed under the tongue, where they dissolve rapidly and are absorbed into the bloodstream directly through the mucous membranes, bypassing the digestive system.

Advantages of Tablets

Tablets offer several advantages as a dosage form:

- Stability: Tablets are stable with respect to their physical, chemical, and microbiological properties.

- Convenience: Tablets are easy to handle, store, and carry, making them an attractive option for patients.

- Accurate Dosing: Tablets provide accurate doses of medication in a stable form.

- Protection of Active Ingredients: The tablet formulation helps protect sensitive active ingredients from exposure to air, moisture, and light.

- Cost-Effective: Tablets are cost-effective to manufacture in large quantities compared to other dosage forms like injectables.

Disadvantages of Tablets

Despite their many advantages, tablets also have some disadvantages:

- Manufacturing Complexity: The manufacturing process for tablets can be complex, especially for coated or modified-release tablets.

- Not Suitable for All Drugs: Some drugs, especially those that are hygroscopic or unstable, may not be suitable for tablet formulation.

- Delayed Absorption: Tablets are subject to individual physiological factors, such as gastric emptying time, which can affect the absorption of the active ingredient.

- Taste Masking: Some tablets may have an unpleasant taste, requiring additional coatings or flavoring agents, which increases production costs.

Quality Control Tests for Tablets

Quality control is essential in ensuring that tablets meet the required standards for efficacy, safety, and consistency. Several tests are performed during tablet manufacturing to ensure that the tablets meet their specifications. These tests include:

- Uniformity of Content This test ensures that the amount of active ingredient in each tablet is consistent. It is particularly important for tablets containing low doses of active ingredients. The test involves sampling a number of tablets and analyzing the drug content. A tablet batch passes if 9 out of 10 tablets meet the specified content limits.

- Uniformity of Weight Tablets must have a consistent weight to ensure that each dose contains the proper amount of active ingredient. The uniformity of weight test involves selecting a sample of tablets, weighing them, and comparing their weights to ensure that no individual tablet deviates significantly from the average weight.

- Disintegration Test The disintegration test measures how long it takes for a tablet to break apart in a specific liquid medium, which simulates the conditions of the gastrointestinal tract. Tablets that do not disintegrate within the prescribed time may not release their active ingredients effectively.

- Dissolution Test The dissolution test is used to assess how quickly the active ingredient in a tablet is released into solution in a given medium. This is important for ensuring that the drug becomes bioavailable and can be absorbed by the body.

- Hardness Test The hardness of a tablet is a measure of its resistance to breaking under pressure. Tablets that are too soft may break during packaging or transportation, while tablets that are too hard may be difficult to swallow.

- Friability Test The friability test measures the tablet’s ability to withstand physical stress during handling and transportation. Tablets are subjected to a tumbling motion, and any loss in weight is measured. Acceptable tablets should lose no more than 1% of their weight.

- Color and Appearance The uniformity of color and appearance of a tablet is also assessed to ensure consistency and to identify any potential defects in the manufacturing process.

Conclusion

Tablets remain one of the most widely used forms of medication, offering numerous benefits in terms of stability, cost-effectiveness, and convenience. With a variety of tablet types, from uncoated to modified-release formulations, patients can receive tailored treatments based on the specific therapeutic needs of the drug. However, despite their advantages, tablets come with certain limitations that must be addressed during the manufacturing process.

Strict quality control tests, such as those for content uniformity, disintegration, dissolution, hardness, and friability, are crucial to ensure that tablets meet the necessary standards for safety and efficacy. By adhering to these rigorous testing procedures, pharmaceutical manufacturers can ensure that tablets provide patients with consistent and reliable therapeutic outcomes.

Leave a Reply