|

Getting your Trinity Audio player ready... |

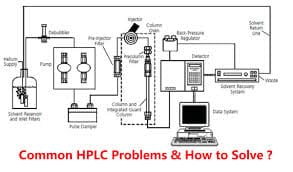

Comprehensive Guide to HPLC Troubleshooting: Common Problems, Causes, and Solutions

HPLC: High-Performance Liquid Chromatography (HPLC) is a sophisticated analytical technique used for separating, identifying, and quantifying compounds in a mixture. Given its complexity, maintaining an optimal system performance and troubleshooting any issues that arise during analysis is crucial. This guide will walk you through pre-analysis checks, common HPLC problems, and effective solutions for each problem.

Pre-Analysis Checks:HPLC

Proper preparation before initiating HPLC analysis is key to ensuring reliable and reproducible results. Below are the essential pre-analysis checks:

- Filter the Mobile Phase & Sample

- Mobile Phase Filtering: Always filter the mobile phase using a 0.45μm filter to remove particulates that may clog the system or interfere with the separation process.

- Sample Filtering: Samples should be filtered with a 0.2μm membrane filter before injection to prevent blockages in the injection valve and the column.

- Temperature Adjustment

- Mobile Phase Temperature: Ensure that the mobile phase has reached room temperature before use. Rapid temperature changes between the freshly prepared mobile phase and the ambient environment can cause baseline instability and drift. If the mobile phase is too cold or hot, it may form bubbles, affecting the flow line and the analysis.

- Purge the Flow Lines

- Remove Bubbles: Air bubbles in the flow lines can result in inaccurate concentration measurements and poor reproducibility. Always ensure that the system is free of bubbles before starting analysis.

- Replace the Mobile Phase as Necessary

Changing the mobile phase is a critical aspect of HPLC maintenance and depends on the specific solvent used. Below are several steps involved in replacing the mobile phase:

- Miscible Solvent: Rinse the mobile phase reservoir filter with the new solvent. After that, purge the flow lines to remove residual solvents and ensure compatibility.

- Immiscible Solvent: If replacing the solvent with an immiscible solvent, start by replacing the old mobile phase with an intermediate solution, then transition to the new mobile phase.

- Buffer Solutions: If the mobile phase contains buffer solutions, it’s essential to replace the old buffer with distilled water first to prevent buffer salts from precipitating, followed by the new mobile phase.

- Verify Autosampler and Rinse Bottles

Before starting the analysis, check the status of the rinse bottles:

- Seal Rinse Bottle: If the mobile phase contains a buffer or phosphoric acid, ensure the rinse bottle is full and will be able to rinse the seals.

- Autosampler Rinse Bottle: Make sure the autosampler rinse bottle is filled with the appropriate mobile phase solution. If it contains salts, use the equivalent salt-free solution to prevent contamination.

- Purge the Autosampler Measuring Pump

When the system has been idle for some time, bubbles may form in the pump head. Purge the pump to remove any air that could cause inconsistencies in injection volume.

Stabilization Checks After Starting the Run

Once the analysis begins, several checks ensure that the system remains stable:

- Leak Check

Leaks in the flow lines can severely affect the analysis. During the analysis, constantly check the system for leaks. If a leak is detected, either tighten the connections or replace the damaged part immediately.

- Check Pump Pressure

Monitor the pump pressure during the analysis. It may vary depending on the pressure settings and the mobile phase used. Ensure that the pressure remains within the desired range.

- Perform a Baseline Check

After starting the analysis, it is essential to ensure that the baseline is stable. A drifting baseline could indicate air bubbles, leaking seals, or an issue with the mobile phase.

- Rinse the Seal

If using a buffer solution or phosphoric acid in the mobile phase, rinse the seal to prevent salt or acid precipitation, which could damage the seal and plunger over time.

- Delivering Rinse Solution

In some cases, the rinse solution may fail to be delivered when the pump is engaged. If this occurs, manually aspirate the rinse solution into the syringe to ensure that it is effectively flushed through the system.

Post-Analysis Checks

After completing the analysis, taking steps to clean and store the system properly is essential for its longevity and performance.

- Rinse the Column

When the instrument is to remain idle for an extended period, rinse the column with a storage solution. The type of solution and method will depend on the type of column in use. Always refer to the manufacturer’s guidelines for column maintenance.

- Clean the Flow Lines

After the analysis, clean the flow lines with an alcohol-based solution, such as isopropyl alcohol or methanol, to prevent mold and bacterial growth. It is essential to disconnect and clean all parts, including the solvent reservoir filter and UV-VIS detector outlet tubing, and store them in a rinse solution to prevent drying out.

Mobile Phase – Solvent Grade and Its Importance

The quality of the mobile phase is critical to HPLC analysis. Below are some essential considerations regarding solvent grade and its potential impact on the results:

- Background Absorption

Solvents with background absorption can cause poor baseline stability, especially during gradient elution. It can result in a reduced linear range and increased noise in the chromatogram. Ensure that only high-quality solvents are used to avoid such problems.

- Water Grade

Different grades of water are used in HPLC, and each has varying degrees of impurity:

- Deionized Water: This water may contain higher amounts of impurities than distilled water, which could contribute to background noise.

- Pure Water Systems: Use pure water systems like those supplied by Millipore or Barnstead for the highest purity. These systems remove both inorganic and organic contaminants effectively.

- Ghost Peaks in Gradient Elution

Low-quality water may cause ghost peaks in gradient elution due to the presence of impurities. Therefore, it is crucial to use high-purity water to avoid this issue.

- Difference Between Analytical and HPLC Grade Solvent

The solvents used for HPLC must be of higher purity than standard analytical solvents to ensure no interference with the analysis.

Mobile Phase – Use of Buffer Solutions

Buffer solutions are commonly used in HPLC to maintain a consistent pH. However, buffer solutions can lead to several issues if not handled correctly.

- Buffer Filtration

Buffer solutions must always be filtered before use to remove particulate matter that could clog the system and affect the separation.

- Risks of Leaving Buffers in the System

Buffer solutions, particularly phosphate buffers, can be a breeding ground for bacterial and fungal growth if left in the system for an extended period. Additionally, buffer salts can crystallize, which could damage the pump and column.

Solvent Premixing and Gradient Elution

For consistent results, proper premixing of solvents is necessary, especially for gradient elution systems:

- For Isocratic Systems: Premix the solvents carefully before use. For example, to prepare a 50:50 mixture of water and methanol, measure equal amounts of each solvent and mix them well.

- Consistency is Key: It is essential to use the same premixing method consistently to ensure reproducibility in results.

Waste Bottle Maintenance

Regular maintenance of the waste bottles is crucial for safe and efficient operation:

- Empty Waste Bottles Regularly: Waste bottles must be emptied frequently to prevent overflow and contamination of the system.

- Avoid Mixing Solvents: Never mix concentrated nitric acid with organic solvents to prevent dangerous reactions.

- Prevent Back Pressure: Do not immerse the drain tubing in waste liquid, as this could create back pressure and disrupt the flow cell.

Common Problems and Solutions in HPLC

HPLC systems can encounter various issues during operation, from pump malfunctions to detector errors. Below are common problems and their solutions:

- Pump-Related Problems

| Problem | Cause | Solution |

| Leaks | Damaged pump seal or piston scratches | Replace pump seal or piston |

| Decreasing Pressure | Insufficient flow, leaks, clogged suction filter | Check connections, tighten or replace components, sonicate or replace filter |

| Increasing Pressure | Blocked flow lines or particulate buildup | Clean or replace blocked components |

| Fluctuating Pressure | Bubbles in the pump head or leaking seals | Purge bubbles, replace seals |

- Injector-Related Issues

| Problem | Cause | Solution |

| Unstable Pressure | Clogged valve | Clean or replace valve rotor seal |

| Leaks | Deteriorated needle seal | Replace needle seal |

| Area Reproducibility | Autosampler not rinsed properly | Check rinsing solvent and ensure thorough rinsing |

- Detector-Related Problems

| Problem | Cause | Solution |

| Leak | Blocked column outlet | Replace outlet tube or gasket |

| Noise | Trapped bubbles or strained cell window | Flush flow cell or replace lamp |

| Drift | Impurities in the mobile phase | Use fresh, covered mobile phase |

- Retention Time Issues

| Problem | Cause | Solution |

| Decreasing Retention Time | Overloaded column, increasing flow rate | Reduce sample load, adjust flow rate |

| Increasing Retention Time | Blocked column, decreasing flow rate | Backflush column, increase flow rate |

Column Treatment and Maintenance

Proper column maintenance is essential to prolong its lifespan and maintain consistent performance.

- Condition New Columns: Condition new or unused columns by running a low flow rate (0.2-0.3 ml/min) for about 30 minutes before starting high-flow operations.

- Gradual Shutdown: When shutting down the system, gradually reduce the flow rate to avoid pressure shock, which can damage the column.

- Flush with Strong Solvents: Regularly flush the column with stronger solvents like acetonitrile to remove strongly absorbed materials.

Useful Tips for Efficient HPLC Maintenance

- Logbook: Keep a detailed logbook for pressure readings, mobile phase composition, and any changes made to the system.

- Routine Maintenance: Always refer to the manufacturer’s instructions and guidelines.

- Problem Diagnosis: When a problem arises, start by observing the instrument’s physical condition. Look for leaks, smell for unusual odors, and feel for temperature fluctuations.