|

Getting your Trinity Audio player ready... |

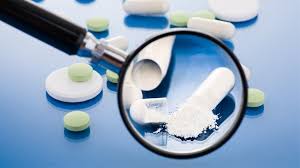

Impurities in New Drug Substances Q3A(R2)

1. Introduction: Impurities

Impurities :This document serves as a guide for the registration process, particularly focusing on the content and qualification of impurities found in new drug substances developed through chemical synthesis. These substances have not been previously registered within a particular region or member state. It does not apply to new drug substances that are being used during the clinical development phase. Moreover, certain types of drug substances are not covered in this guideline, including biological or biotechnological drugs, peptides, oligonucleotides, radiopharmaceuticals, fermentation-derived products, semi-synthetic substances, herbal products, and crude substances originating from animals or plants.

Impurities in new drug substances are examined from two primary perspectives:

- Chemical Aspects: These include the classification, identification, and reporting of impurities, as well as the listing of impurities in specifications and a brief overview of the analytical procedures.

- Safety Aspects: These aspects provide guidance on how to qualify impurities that were not present, or were present in much lower amounts, in batches of new drug substances used in safety and clinical studies.

2. Classification of Impurities

Impurities found in new drug substances can be categorized into three main groups:

- Organic Impurities (Process- and Drug-Related): These are impurities that may arise during the manufacturing process and/or storage of the drug substance. They include:

- Starting materials

- By-products

- Intermediates

- Degradation products

- Reagents, ligands, and catalysts

- Inorganic Impurities: These impurities typically result from the manufacturing process. They are usually known and include:

- Reagents, ligands, and catalysts

- Heavy metals or other residual metals

- Inorganic salts

- Other materials (e.g., filter aids, charcoal)

- Residual Solvents: These are inorganic or organic solvents used in the preparation of solutions or suspensions during synthesis. The selection and control of residual solvents are guided by the ICH Q3C Guideline on Residual Solvents.

Certain categories of substances are not addressed in this document:

- Extraneous Contaminants: These should not appear in drug substances and are typically managed under Good Manufacturing Practice (GMP).

- Polymorphic Forms and Enantiomeric Impurities: These are also excluded from this guideline.

3. Rationale for Reporting and Controlling Impurities

The applicant must provide a comprehensive summary of the impurities most likely to arise during the synthesis, purification, and storage of the new drug substance. This should be based on a thorough scientific analysis of the chemical reactions involved in the synthesis, impurities from raw materials, and potential degradation products.

Additionally, the applicant should summarize the laboratory studies conducted to identify impurities in the new drug substance. This should include test results from batches manufactured during both the development phase and the proposed commercial process, as well as results from stress testing (as outlined in the ICH Q1A Guideline on Stability). The impurity profile of the drug substance batches intended for marketing must be compared with those used in earlier development, and any differences should be discussed.

For impurities present at levels greater than the identification threshold (as defined in Attachment 1), the structure of the impurities should be described. Any degradation product observed in stability studies, which exceeds the identification threshold, must also be identified. If the identification of an impurity is not feasible, the applicant should include a summary of the failed identification attempts.

The identification of impurities at levels lower than the threshold is generally not required. However, the applicant should develop analytical procedures for impurities that could have significant pharmacological or toxicological effects, even at levels below the identification threshold.

3.1 Organic Impurities

The applicant must identify and summarize any potential organic impurities that could arise during synthesis, storage, and purification. This includes impurities from starting materials, by-products, intermediates, degradation products, and catalysts or reagents used in the manufacturing process.

The impurity profile must include batches of the drug substance from both development and the proposed commercial process. A comparison of these profiles will help to ensure consistency and to identify any new or unforeseen impurity that may arise under commercial conditions.

3.2 Inorganic impurity

Inorganic impurity should be monitored throughout the development and manufacturing process. The evaluation should focus on the presence of residual catalysts and metals, which should be identified and quantified using appropriate pharmacopoeial procedures. These impurity should be controlled based on known safety data or pharmacopoeial standards.

The need to control inorganic impurity in the final drug substance should be carefully discussed. Impurity thresholds should be based on available safety data, and the manufacturing process should be validated to ensure impurity levels remain within acceptable limits.

3.3 Residual Solvents

The presence of residual solvents from the manufacturing process must be carefully monitored. The ICH Q3C Guideline for Residual Solvents provides standards for acceptable levels of these solvents. The applicant must ensure that solvent residues are controlled and that their presence does not exceed safety limits established for the drug substance.

4. Analytical Procedures

For the purpose of registration, the applicant must provide evidence that the analytical methods used to detect and quantify impurities have been validated. The validation should demonstrate that the methods are robust and suitable for routine use in quality control processes. Methods such as chromatography or spectroscopy may be used to identify and quantify both identified and unidentified impurities.

The selection of analytical methods should be based on the level of sensitivity required for the impurity profile of the new drug substance. If necessary, the analytical procedure may use a correction factor if the impurity response differs from that of the drug substance. The reporting threshold for impurity should not exceed the limits that can be reliably detected by the validated methods.

Analytical procedures should be discussed, and the applicant must justify any differences between the analytical methods used in development and those proposed for commercial production. For example, the use of lower precision techniques, such as thin-layer chromatography, can be acceptable when justified.

5. Reporting Impurity Content of Batches

In the registration application, the applicant must include detailed impurity content data for all batches used in clinical trials, stability testing, and those produced through the proposed commercial process. Results should be reported in numerical form and not as generalized statements like “complies” or “meets limit.” impurity present at levels exceeding the reporting threshold must be listed individually, and the total impurity content should also be reported.

For impurities at levels greater than the reporting threshold but below 1.0%, results should be reported to two decimal places (e.g., 0.06%, 0.13%). impurity at 1.0% or above should be reported to one decimal place (e.g., 1.3%). The results should be tabulated and linked to the corresponding analytical methods.

The report must include a clear description of the analytical methods used and should contain chromatograms or other data showing the separation and identification of impurity . Where changes in analytical procedures occur, the applicant must link the results to the method used and provide validation data.

6. Listing of Impurities in Specifications

The specification for a new drug substance should include a list of impurity , based on stability studies, chemical development work, and routine batch analysis. The list should include all impurities identified in batches produced by the proposed commercial process. The impurity profile observed in earlier batches used in clinical and safety studies should also be considered.

- Specified Impurities: These are the impurity that are either identified or unidentified but are present at levels above the identification threshold.

- Unspecified Impurities: These are impurities present below the identification threshold, but still subject to acceptance criteria.

- Residual Solvents and Inorganic impurity : These must also be included in the impurity profile.

Acceptance criteria should be based on safety data and the level achievable through the manufacturing process and analytical methods. impurity that are unusually potent or that produce adverse pharmacological effects should be subject to stricter controls.

7. Qualification of Impurities

Qualification is the process of ensuring that an impurity or a specific impurity profile is safe at the specified level. The applicant must provide a scientific rationale for the acceptance criteria of impurity , considering safety and clinical data. Any impurity found in drug substances that have been tested in safety or clinical studies is considered qualified.

Qualification thresholds can vary depending on the nature of the impurity, the drug class, and the therapeutic use. In certain cases, such as when impurity are known to be associated with adverse effects, stricter thresholds may be applied. Conversely, for drugs with a lower safety concern, higher thresholds may be acceptable.

If the available data does not qualify an impurity at the proposed level, the applicant may need to conduct additional safety testing to establish the acceptable level. Qualification studies should consider the drug’s intended patient population, dose, and route of administration.

In cases where new impurity are observed in later stages of development, they must be identified if their levels exceed the identification threshold. Similarly, their qualification should be evaluated based on their potential safety risks.

Conclusion

The control and qualification of impurity in new drug substances are critical aspects of the drug development process. By classifying impurity , using validated analytical methods, and establishing appropriate reporting thresholds, pharmaceutical companies can ensure the safety and efficacy of their products. The guidelines set forth in this document provide a structured approach to managing impurities and offer a framework for their control throughout the manufacturing and development phases.