|

Getting your Trinity Audio player ready... |

Biotechnological/Biological Products Specifications: Test Procedures And Acceptance Criteria

1. Objective and Background: Biotechnological/Biological

Biotechnological/Biological: Objective: The document provides general principles for setting and justifying specifications for biotechnological and biological products, specifically proteins, polypeptides, and their derivatives, produced from recombinant or non-recombinant cell culture expression systems.

Background: Specifications define the tests, procedures, and acceptance criteria needed to ensure that the product conforms to quality standards. They are critical in ensuring the safety and efficacy of biotechnological products, and they should be based on extensive product characterization during the development phase.

2. Principles for Setting Specifications

- 2.1 Characterization: Product characterization is critical and involves determining physicochemical properties, biological activity, immunochemical properties, and purity. Specifications are based on data from clinical and preclinical studies, manufacturing consistency data, and stability studies.

- 2.1.1 Physicochemical Properties:

- Physicochemical characterization should include the composition, primary structure, and possibly the higher-order structure of the product.

- Heterogeneity, a natural aspect of proteins due to post-translational modifications, should be understood. If the product has variants that do not negatively impact efficacy or safety, they may be considered product-related substances and not impurities.

- 2.1.2 Biological Activity:

- Biological activity is assessed through assays, such as animal-based assays, cell culture-based assays, and biochemical assays. Potency, which quantifies biological activity, is linked to the biological properties that are important for clinical outcomes.

- Where biological assays are used, they should be referenced against international or national standards. If no standard exists, in-house reference materials may be used.

- Biological assays can be substituted with physicochemical tests in certain circumstances, provided there’s adequate correlation to biological activity.

- 2.1.3 Immunochemical Properties:

- If the product is an antibody, immunological properties (such as binding affinity and immunoreactivity) should be characterized.

- Binding assays and epitope definition may be necessary to fully characterize the product.

- 2.1.4 Purity, Impurities, and Contaminants:

- Purity: The purity of a biological product is determined through multiple analytical methods, taking into account product-related substances and variations arising during manufacturing or storage.

- Impurities: Impurities may be process-related (e.g., host cell proteins, antibiotics) or product-related (e.g., degradation products). Manufacturers should evaluate both types and set appropriate acceptance criteria based on preclinical and clinical data.

- Contaminants: Unintended materials (such as microbial species or chemical contaminants) must be avoided. For viral or mycoplasma contamination, specialized strategies for evaluation and control are necessary, as outlined in other ICH guidelines.

3. Test Procedures for Biotechnological/Biological Products

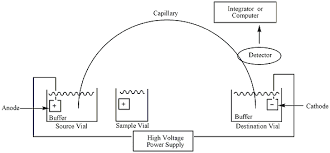

- The document emphasizes the use of validated and appropriate analytical methods to assess all relevant attributes (e.g., purity, potency, and impurities) of biotechnological products.

- New and evolving technologies should be adopted where appropriate.

4. Setting Acceptance Criteria

- Acceptance criteria for biotechnological and biological products must be based on extensive data from preclinical, clinical, and stability studies.

- The focus is on ensuring product quality and consistency rather than full product characterization, though full characterization may be required during development or in cases of significant process changes.

5. Incorporation of New Analytical Methods

- The document stresses the importance of leveraging new analytical technologies and methodologies as they become available, provided they are appropriate for the product in question.

6. Special Considerations for Specific Product Types

- Antibodies: Immunochemical testing for antibodies should assess binding, affinity, avidity, and cross-reactivity to ensure their functionality.

- Proteins/Polypeptides: These can include different post-translational modifications that contribute to the heterogeneity of the product, and thus, testing should include assessments of this variability.

- Impurities and Contaminants: Manufacturers are encouraged to characterize and test for both process-related and product-related impurities to ensure they do not affect safety or efficacy.

7. Quantity and Assay:

- Quantity, often measured as protein content, is crucial for biotechnological and biological products. This should be determined using physicochemical assays, and in some cases, it may be correlated with biological assays.

- When this correlation exists, it may be appropriate to use quantity measurement (instead of biological activity) during manufacturing processes.

8. Reference Standards and Materials:

- For new molecular drug applications, an internationally recognized standard might not be available. In such cases, an in-house primary reference material must be established, especially if the drug is produced at commercial scale.

- In cases where national or international standards exist, the in-house material should be calibrated against them.

- Reference materials may differ for product-related substances, impurities, or process-related impurities, and they should be characterized and stored appropriately.

9. Validation of Analytical Procedures:

- The analytical methods used in drug testing must be validated, according to ICH guidelines, at the time of submission to regulatory authorities, except for specific tests unique to biotechnology.

10. Process Control and In-process Testing:

- A well-designed manufacturing process ensures that a drug product consistently meets specifications. In-process tests are done at critical steps to confirm consistency and can sometimes eliminate the need for further testing of the drug substance or product.

- Action limits and acceptance criteria should be set for these tests.

11. Specifications:

- Specifications are essential for defining the quality of drug substances and drug products. These should be based on data from clinical and preclinical trials, consistency studies, and stability tests.

- Specifications may vary for drug substances and drug products but should include tests for purity, identity, quantity, and potency, among others.

- Acceptance criteria should be justified based on development and manufacturing data.

12. Stability and Shelf-life:

- Specifications must consider potential degradation of the drug during storage, which may affect the product’s quality. The manufacturer should propose a stability profile to identify any changes over time.

- This concept also distinguishes between release limits (tighter) and shelf-life limits (more lenient).

13. Drug Substance Specifications:

- Drug substances should be characterized for appearance, identity, purity, potency, and quantity.

- Impurities should be classified as process-related (from the production process) or product-related (from product variants).

- Potency assays must be validated for each drug substance.

14. Drug Product Specifications:

- Similar to drug substances, drug products must meet specifications for appearance, identity, purity, potency, and quantity.

- Additional testing may be needed for specific dosage forms or if impurities are formed during product storage.

15. Pharmacopoeial Specifications:

- Pharmacopeial tests (such as for sterility, endotoxins, microbial limits) must be included when relevant. These tests and their methods must align with established pharmacopoeias.

16. General Tests:

- For drug products, tests such as pH, osmolarity, and uniformity of dosage units are also important.

- Certain dosage forms may require additional, specific tests, depending on the product.

Conclusion

- The document emphasizes the need for manufacturers to perform extensive characterization and testing throughout product development, while utilizing evolving analytical technologies and adhering to regulatory guidelines.

- Specifications should focus on key aspects of the product that ensure its safety, efficacy, and quality, while testing methods should be continually updated based on advancements in analytical techniques.