|

Getting your Trinity Audio player ready... |

Impact of Granule Particle Size on Dissolution of BCS Class II and IV Drugs

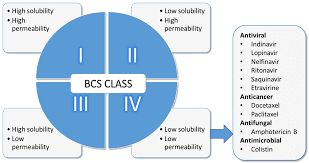

Granule Particle Size: Drug development and formulation science often revolve around one central theme: how efficiently a drug dissolves in the body. Dissolution is a prerequisite for absorption, and therefore, bioavailability. For drugs classified under the Biopharmaceutics Classification System (BCS), particularly Class II (low solubility, high permeability) and Class IV (low solubility, low permeability), dissolution presents a critical challenge. One of the most influential formulation variables in this regard is granule particle size.

This article explores how the size of granules can dramatically affect the dissolution performance of BCS Class II and IV drugs, along with its implications for pharmaceutical manufacturing and therapeutic success.

Understanding the Basics:Granule Particle Size

The Biopharmaceutics Classification System (BCS) categorizes drugs based on their solubility and permeability characteristics.

- BCS Class II drugs: These compounds exhibit poor aqueous solubility but can permeate biological membranes effectively. Their bioavailability is primarily dissolution-limited.

- BCS Class IV drugs: These represent the most problematic category, with both poor solubility and poor permeability. For such drugs, formulation scientists must optimize dissolution to the maximum possible extent before addressing permeability barriers.

Since dissolution is the critical rate-determining step in both classes, any strategy that enhances the dissolution process becomes essential. Particle size reduction and control during granulation is one such strategy.

How Particle Size Affects Dissolution

- Surface Area and Dissolution Rate

One of the most fundamental relationships in pharmaceutics is between particle size and surface area. Smaller particles expose a significantly larger surface area relative to their volume. According to the Noyes–Whitney equation, the dissolution rate is directly proportional to the available surface area of the drug exposed to the solvent.

- Smaller granules: Dissolve faster due to increased surface area, making them advantageous for poorly soluble BCS Class II and IV drugs.

- Larger granules: Dissolution is slower, but they improve flowability and handling during manufacturing, making processes like tableting more efficient.

Thus, formulation scientists often balance between the rapid dissolution benefits of smaller particles and the manufacturing advantages of larger granules.

- Porosity and Wetting

Another important factor influenced by granule size is porosity—the void spaces within a particle bed that allow solvent penetration. Smaller particles usually generate granules with higher porosity, which in turn promotes faster wetting and quicker penetration of the dissolution medium.

- Enhanced wetting leads to more efficient disintegration and dissolution.

- However, excessive particle size reduction can negatively impact compressibility. Very fine powders tend to be cohesive and may exhibit poor compaction properties, leading to weak tablets or poor mechanical strength.

Hence, while reducing particle size accelerates dissolution, there is a practical lower limit beyond which compressibility and flowability are compromised.

- Granule Size Distribution

It is not only the average granule size that matters but also the distribution of sizes within a batch. A narrow and uniform size distribution ensures consistency in dissolution profiles, reducing batch-to-batch variability and enhancing product reliability.

In contrast, a wide distribution may lead to mixed performance: some particles dissolve too rapidly while others lag, creating variability in bioavailability. Optimizing both the mean particle size and the distribution is, therefore, a critical design goal.

Why This Matters for BCS Class II and IV Drugs:Granule Particle Size

The role of granule particle size becomes especially important when applied to the unique challenges posed by BCS Class II and IV drugs.

For BCS Class II Drugs

Since these drugs are permeability-favored but dissolution-limited, improving solubility through particle size control has a direct impact on absorption and bioavailability. Smaller granules accelerate dissolution, ensuring that sufficient amounts of the drug reach solution form at the site of absorption. In this way, therapeutic efficacy is significantly enhanced.

For BCS Class IV Drugs

These compounds pose a dual challenge: low solubility and low permeability. Here, dissolution optimization becomes a crucial first step. While reducing particle size alone may not completely resolve the bioavailability issue, it helps maximize the fraction of drug available in solution, which is a prerequisite for absorption. Other strategies, such as permeation enhancers or advanced drug delivery systems, can then build upon this foundation.

In both cases, controlling granule size can convert formulation difficulties into therapeutic opportunities.

Practical Considerations in Formulation Development:Granule Particle Size

When deciding the ideal particle size range for granulation, pharmaceutical scientists must weigh multiple competing factors:

- Flow Properties

Larger granules typically exhibit better flow during processing, which is essential for uniform die filling in tablet compression.

- Compressibility

Finer powders may resist compaction or produce weak tablets. A balance must be struck between optimal dissolution and acceptable mechanical strength. - Stability

Smaller particles with high surface energy can sometimes be more prone to chemical degradation or moisture uptake. - Process Feasibility

Achieving ultra-fine particles may require techniques like micronization or nanonization, which can be costly and difficult to scale up.

Ultimately, the target particle size distribution is a compromise tailored to each drug’s physicochemical properties, the intended dosage form, and manufacturing constraints.

Techniques for Particle Size Optimization

Several strategies are employed in the pharmaceutical industry to achieve the desired granule size and dissolution performance:

- Milling and micronization: Mechanical size reduction using jet mills or ball mills to increase surface area.

- Spray drying: Produces fine, porous particles with high surface area.

- Controlled crystallization: Alters crystal habit and size to improve dissolution.

- Granulation techniques (wet, dry, or melt): Used to create granules of specific sizes and improve flowability while retaining dissolution advantages.

- Nanotechnology approaches: Nanoparticles and nanosuspensions drastically increase surface area and can transform poorly soluble drugs into bioavailable products.

Case Examples:Granule Particle Size

- For a poorly soluble Class II drug such as itraconazole, micronization has been shown to improve dissolution significantly, leading to better systemic exposure.

- In contrast, with a Class IV drug like hydrochlorothiazide, dissolution enhancement through particle size control is essential but not sufficient alone; permeability enhancers must also be employed.

These examples highlight that granule size optimization is often a necessary but not always sufficient step in the formulation pathway.

Conclusion

Granule particle size plays a decisive role in determining the dissolution behavior of BCS Class II and IV drugs, where solubility challenges dominate the bioavailability landscape. Smaller granules generally promote faster dissolution by increasing surface area and porosity, but they can compromise flow and compressibility if reduced excessively. Larger granules aid in processing but may slow dissolution.

By carefully tailoring granule size and distribution, pharmaceutical scientists can strike a balance between manufacturability and therapeutic performance. For Class II drugs, this often translates directly into improved bioavailability, while for Class IV drugs it serves as a foundational step toward overcoming both solubility and permeability barriers.

In essence, the right granule size transforms limitations into opportunities, enabling better formulation strategies and ultimately enhancing patient outcomes