|

Getting your Trinity Audio player ready... |

Understanding the Core Components of a Film Coating System

A film coating system is an essential tool in the pharmaceutical and food industries, providing a precise and efficient way to apply coatings to tablets and other similar products. This system consists of several key components that contribute to its functionality, accuracy, and efficiency. These components work together seamlessly to ensure a smooth, uniform coating that is both effective and durable. The system typically includes six main parts, each with its unique role in the process.

1. Automatic Control System (PLC) Film Coating System

At the heart of a film coating system lies the automatic control system, which is often managed by a programmable logic controller (PLC). The PLC is the brain of the operation, allowing operators to configure and control various parameters that determine the accuracy, consistency, and efficiency of the coating process. It is a critical component for ensuring that the system operates smoothly, as it can store and recall process data, adjust settings as required, and even monitor the performance of the equipment in real time.

The PLC enables users to pre-program all necessary settings before initiating the coating process. It allows operators to define parameters such as spray rates, air flow, temperature, and the duration of the coating cycle. Additionally, the control system can display key process data and has the capability to record and print the operational status of the equipment, providing operators with important insights into the system’s performance. This level of automation and control ensures that the coating process is carried out accurately and consistently, minimizing human error and maximizing productivity.

2. Electronic Motors

Electronic motors play a vital role in a film coating system by providing the power required for several critical processes, including creating negative pressure, circulating air, and mixing tablets. These motors are distributed across various components within the system, ensuring that the equipment operates smoothly and efficiently.

Some of the areas where motors are used include:

- Peristaltic Pump Systems: These pumps are responsible for moving the coating solution through the system in a controlled and precise manner. They ensure that the solution is delivered evenly to the tablets during the coating process.

- Exhaust Air System: The exhaust system is responsible for removing excess air and vapor from the coating chamber. It ensures that the environment within the chamber remains optimal for the coating process.

- Hot Air Equipment: Motors in the hot air system generate the airflow necessary for drying the coated tablets, ensuring that the coating is properly set and the solvent is evaporated.

- Coating Drum: The coating drum is powered by motors that help rotate the tablets during the coating process, ensuring that they are evenly coated.

In many systems, multiple motors are used in combination to handle different tasks simultaneously. The number of motors and their specific functions will depend on the design of the film coating system and the complexity of the coating process.

3. Touch Screen Operation Panel

A touch screen operation panel provides a user-friendly interface for operators to interact with the film coating system. This panel serves as the primary control interface, allowing users to configure settings, monitor the system’s performance, and make adjustments in real-time.

The interface is designed to be intuitive and easy to use, making it simple for operators to input data, view system parameters, and troubleshoot any issues that may arise. This convenience reduces the learning curve associated with operating the system and enhances overall operational efficiency. Through the touch screen, users can access detailed process data, configure spray rates, adjust air flow, and fine-tune other essential parameters to achieve the desired coating results.

4. Guide Plate

The guide plate is an important part of the system that helps direct the movement of the tablets as they interact with the coating solution. It ensures that the tablets are evenly coated by facilitating proper mixing with the solution. By guiding the tablets through the coating chamber, the guide plate ensures that the coating process is uniform and that each tablet receives a consistent layer of coating material.

In addition to improving the quality of the coating, the guide plate also prevents damage to the tablets. It helps to minimize the risk of tablet breakage during the coating process by preventing the adhesion of coating materials to the tablets. This is particularly important, as any damage to the tablets can compromise their effectiveness or integrity.

5. Peristaltic Pump

The peristaltic pump is a critical component of the film coating system that simplifies the spraying process and stabilizes atomization. It ensures that the coating solution is delivered to the spray nozzles in a controlled and consistent manner, allowing for the production of thin, even film coats on the tablets. The peristaltic pump works by pushing the solution through a flexible tubing system, creating a steady flow without introducing air bubbles or inconsistencies.

This pump helps to maintain uniformity in the coating process by ensuring that the solution is atomized properly and applied evenly to the tablets. Without this level of precision, the coating could become too thick in some areas and too thin in others, leading to inconsistent results. The peristaltic pump is essential for achieving the desired coating thickness and quality.

6. Spraying System

The spraying system is a critical part of the film coating system, responsible for atomizing the coating solution and applying it to the tablets. It typically consists of several key components, including a tank to hold the coating solution, nozzles for spraying the solution, and a pump to facilitate the flow of the solution to the nozzles.

The design of the spraying system is focused on simplicity and ease of maintenance. By making the system easy to clean, operators can prevent blockages and ensure that the system operates at peak efficiency. The spray nozzles are designed to atomize the coating solution into fine droplets, which are then sprayed onto the rotating tablets as they pass through the coating drum.

The spraying system is also designed to minimize wastage of the coating solution. The nozzles are strategically positioned to ensure that the solution is applied only to the tablets, preventing overspray and reducing the amount of solution that is lost. This efficient use of the coating solution helps to keep costs down and reduces the environmental impact of the process.

Additional Components of the Film Coating System

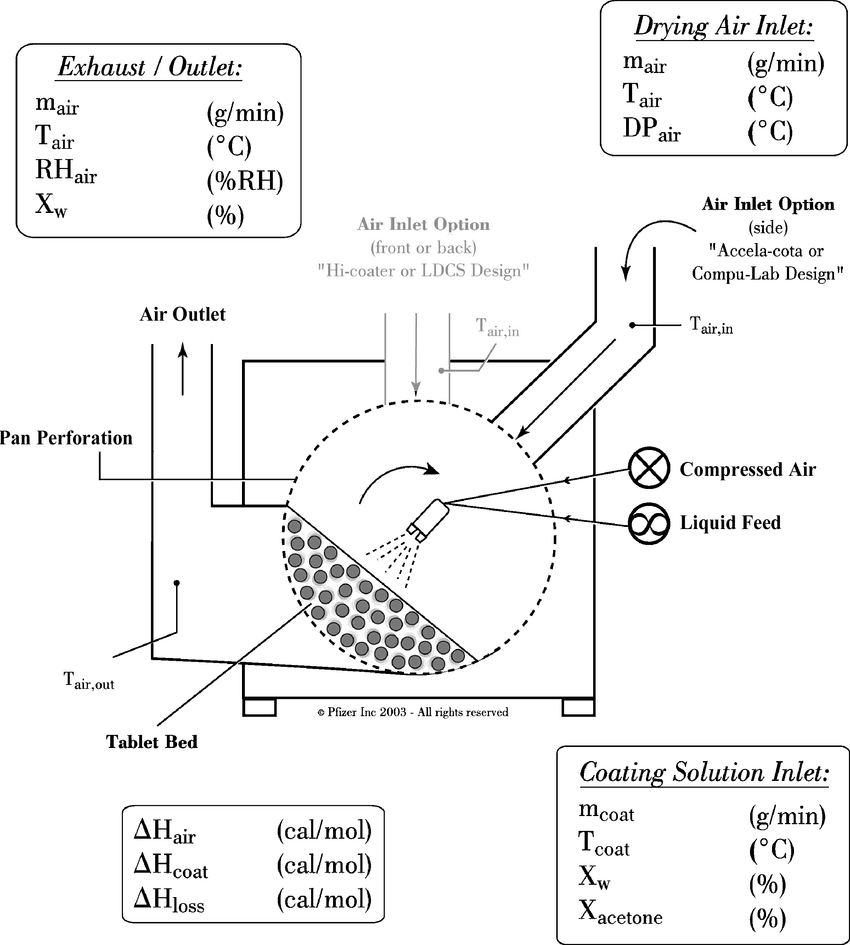

Beyond the six main components mentioned above, there are several other parts that contribute to the overall functionality of the system. These include the inner air supply, exhaust system, tablet pan, atomizing air, air suck, and tablet bed. Each of these components plays a role in maintaining the optimal conditions for the coating process, whether it’s controlling the temperature, ensuring proper airflow, or facilitating the smooth rotation of the tablets.

The Working Process of a Film Coating System

The operation of a film coating system is typically automated, ensuring that the entire process is carried out with minimal human intervention. To begin, a polymer is dissolved in a solvent, and additional ingredients such as plasticizers, colorants, and opacifiers are added to the solution. This mixture forms the coating that will be applied to the tablets.

Once the solution is prepared, the tablets are loaded into the coating drum. The drum rotates, allowing the tablets to move through the coating chamber, where the coating solution is atomized and sprayed onto the tablets. The spraying system ensures that the solution is evenly applied to each tablet, while the guide plate helps direct the flow of tablets to ensure consistent coating.

As the tablets continue to rotate, hot air is introduced to remove the solvent from the coating solution, allowing it to set and form a thin film on each tablet. The tablets are then dried to remove any remaining solvent, resulting in a smooth, uniform coating.

Considerations When Importing a Film Coating System

When importing a film coating system, several factors should be considered to ensure that the system meets operational requirements. These include the need for an adequate supply of process air for efficient drying, the ability to maintain a narrow temperature range, and the ease of cleaning and maintenance.

Additionally, it is important to ensure that the system is capable of handling flammable solvents safely, with in-built explosion prevention features. Compliance with regulatory standards, such as cGMP and environmental regulations, is also essential.

Moreover, sensors should be incorporated to monitor key parameters such as air temperature, pan rotation speed, and the spray rate, helping operators maintain optimal conditions for the coating process.

Conclusion

A film coating system is a complex piece of equipment composed of several critical components that work together to ensure the uniform, efficient, and consistent application of coatings to tablets and other products. By understanding the role of each component and the way the system operates, manufacturers can ensure that their products meet the highest quality standards while maximizing efficiency and reducing waste.