|

Getting your Trinity Audio player ready... |

General Principles of Residual Solvents in Pharmaceutical Products Q3C(R9)

Classification of Residual Solvents Based on Risk Assessment: Residual Solvents

Residual Solvents: In the pharmaceutical industry, residual solvents are chemical substances that may remain in drug products following the manufacturing process. These solvents can potentially pose health risks, especially when consumed in quantities above certain safety thresholds. The assessment of these solvents is critical for ensuring drug safety. Several organizations, such as the International Program on Chemical Safety (IPCS) and the World Health Organization (WHO), have developed systems to classify these solvents based on their toxicity.

The term Tolerable Daily Intake (TDI), coined by the IPCS, refers to the maximum amount of a substance that a person can be exposed to each day over a lifetime without posing a significant risk of harm. Similarly, the Acceptable Daily Intake (ADI) is used by WHO and other national health authorities to define safe exposure levels. However, the guideline introduces a new term, Permitted Daily Exposure (PDE), to address discrepancies in ADI values for the same substance. This term reflects the pharmaceutically acceptable intake of residual solvents, providing a clearer distinction between substances with different health risk assessments.

The classification of residual solvents is based on their potential to harm human health, and these solvents are grouped into three primary classes:

- Class 1 solvents: These solvents should be completely avoided due to their significant human toxicity and environmental risks. They are known to be carcinogenic or are strongly suspected of being carcinogenic, and they pose severe environmental hazards.

- Class 2 solvents: These solvents are toxic, but their risks can be mitigated with proper controls. They are either animal carcinogens or may cause other serious health issues such as neurotoxicity or teratogenicity. These solvents may also cause reversible toxicity, and therefore their levels need to be limited.

- Class 3 solvents: Solvents in this class have low toxicity and pose minimal risk to human health. For these substances, no health-based exposure limit is required, and the PDE is considered to be 50 mg or more per day.

Residual solvents are listed and evaluated for their health risks in Appendix 1, and the class of each solvent is determined based on their toxicological profile and potential impact on human health.

Methods for Establishing Exposure Limits

To determine the permissible exposure levels for each solvent, a comprehensive method is employed, detailed in Appendix 3. This method takes into account the available toxicological data for each solvent, which are then used to establish safe daily exposure limits. The guidelines for assessing exposure and setting limits were first published in Pharmeuropa, Vol. 9, No. 1, Supplement, April 1997.

A solvent’s permitted daily exposure (PDE) is established based on various scientific studies that evaluate its toxicological effects. These studies include animal testing, human exposure scenarios, and epidemiological data. For each solvent, an appropriate safety factor is applied to ensure that the PDE reflects the substance’s toxicity under worst-case exposure conditions. This allows pharmaceutical manufacturers to produce drug products with minimal risk of toxic exposure while ensuring therapeutic efficacy.

Options for Describing Limits of Class 2 Solvents

When setting limits for Class 2 solvents, two options are available to ensure the safe use of these solvents in drug products:

- Option 1: This option provides concentration limits in parts per million (ppm) for solvents in pharmaceutical products. These limits are calculated using the following formula:

Concentration (ppm)=1000×PDEDose\text{Concentration (ppm)} = \frac{1000 \times \text{PDE}}{\text{Dose}}Concentration (ppm)=Dose1000×PDE

In this formula, PDE is given in milligrams per day (mg/day), and Dose is the mass of the drug product in grams (g). This approach is applicable when the daily dose of a drug is either unknown or variable. If all excipients and active ingredients in a formulation fall within the specified limits, no further calculations are required, assuming the daily dose does not exceed 10 grams. For doses greater than 10 grams, Option 2 should be considered.

- Option 2: This option is used when it is not necessary for each individual component of a drug product to comply with the limits set in Option 1. Instead, manufacturers calculate the total permissible amount of residual solvent in the entire drug product by considering the maximum daily dose and the PDE for each solvent. This allows flexibility, particularly in complex drug formulations with multiple components. However, the total residual solvent exposure must not exceed the allowed PDE, and the manufacturer must demonstrate that efforts have been made to minimize solvent content to the lowest possible level.

For example, in the case of acetonitrile in a drug product, the permissible daily exposure is 4.1 mg. Using Option 1, the concentration limit is calculated to be 410 ppm. If a drug product contains multiple excipients, the concentration of acetonitrile in each component is calculated and summed. If the total exposure does not exceed the 4.1 mg limit, the product is considered safe. If it does, additional steps must be taken to reduce the residual solvent.

Analytical Procedures for Measuring Residual Solvents

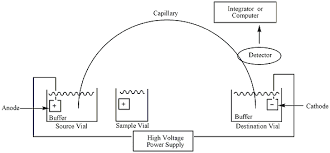

To ensure compliance with the established exposure limits, manufacturers must accurately measure the residual solvents present in drug products. The most commonly used method for detecting residual solvents is gas chromatography, which is a precise analytical technique capable of identifying and quantifying trace amounts of solvents in complex drug formulations.

Pharmacopoeial standards provide harmonized procedures for determining residual solvents, which should be followed whenever possible. However, manufacturers can also select alternative validated analytical methods that best suit their specific requirements. It is important to note that if only Class 3 solvents are present, non-specific methods like loss on drying may be used, provided they are properly validated.

The validation of analytical methods must adhere to the guidelines provided by the International Council for Harmonisation (ICH), specifically the Q2 guidelines on the validation of analytical procedures. This ensures that the methods are accurate, reliable, and suitable for their intended purpose.

Reporting Residual Solvent Levels

To comply with the guidelines, manufacturers need to provide specific information regarding the content of residual solvents in their drug products. This information must be obtained from suppliers of excipients and drug substances, who are expected to supply relevant data on the types and concentrations of residual solvents. Acceptable examples of statements that suppliers could provide include:

- “Only Class 3 solvents are likely to be present, and the loss on drying is less than 0.5%.”

- “Only Class 2 solvents X, Y, and Z are likely to be present, and all are below the Option 1 limit.”

- “Only Class 2 solvents X, Y, and Z and Class 3 solvents are likely to be present. Residual Class 2 solvents are below the Option 1 limit, and Class 3 solvents are below 0.5%.”

If Class 1 solvents are present, they should be explicitly identified and quantified. Additionally, solvents that exceed the established limits for Class 2 or Class 3 solvents must also be identified and quantified.

Limits for Residual Solvents in Pharmaceutical Products

Solvents to Be Avoided (Class 1)

Solvents in Class 1 are classified as toxic and environmentally harmful substances. These solvents should not be used in the manufacturing of drug products, excipients, or drug substances, except in cases where their use is deemed unavoidable to produce a drug product with significant therapeutic benefits. In such cases, the levels of these solvents should be strictly controlled.

The following solvents are classified as Class 1 solvents, and their use should be minimized or eliminated in pharmaceutical manufacturing:

| Solvent | Concentration Limit (ppm) | Concern |

| Benzene | 2 | Carcinogen |

| Carbon tetrachloride | 4 | Toxic and environmental hazard |

| 1,2-Dichloroethane | 5 | Toxic |

| 1,1-Dichloroethene | 8 | Toxic |

| 1,1,1-Trichloroethane | 1500 | Environmental hazard |

Solvents to Be Limited (Class 2)

Solvents in Class 2 have inherent toxicity, but their use can be permitted under controlled conditions. These solvents include those that are carcinogenic in animals or may cause irreversible damage to human health, such as neurotoxicity or teratogenicity. The permitted daily exposure (PDE) for these solvents is specified in milligrams per day (mg/day), and the concentration limits are given in parts per million (ppm).

Here is a sample list of Class 2 solvents with their respective PDEs and concentration limits:

| Solvent | PDE (mg/day) | Concentration Limit (ppm) |

| Acetonitrile | 4.1 | 410 |

| Chlorobenzene | 3.6 | 360 |

| Chloroform | 0.6 | 60 |

| Cumene | 0.7 | 70 |

| Cyclohexane | 38.8 | 3880 |

| Cyclopentyl methyl ether | 15.0 | 1500 |

Solvents with Low Toxic Potential (Class 3)

Class 3 solvents are considered to be less toxic and do not pose significant risks to human health at normal exposure levels. These solvents include substances like acetone and ethanol, which are widely used in pharmaceutical manufacturing due to their relatively low toxicity.

While it is not necessary to set strict exposure limits for Class 3 solvents, good manufacturing practices (GMP) should still be followed to minimize their presence in drug products. The typical concentration limit for Class 3 solvents is 50 mg per day (or 5000 ppm), though higher levels may be acceptable if they align with current manufacturing capabilities and safety standards.

Solvents for Which No Adequate Toxicological Data is Available

There are certain solvents for which no adequate toxicological data exist to establish a PDE. These solvents should be used with caution, and manufacturers must provide justification for the levels of residual solvents present in their products. Examples of such solvents include:

| Solvent | Toxicological Data Status |

| 1,1-Diethoxypropane | Insufficient data |

| Methylisopropyl ketone | Insufficient data |

| Petroleum ether | Insufficient data |

In the absence of sufficient data, the manufacturer must conduct their own safety assessments and ensure that the levels of these solvents in their products do not exceed safe limits.