|

Getting your Trinity Audio player ready... |

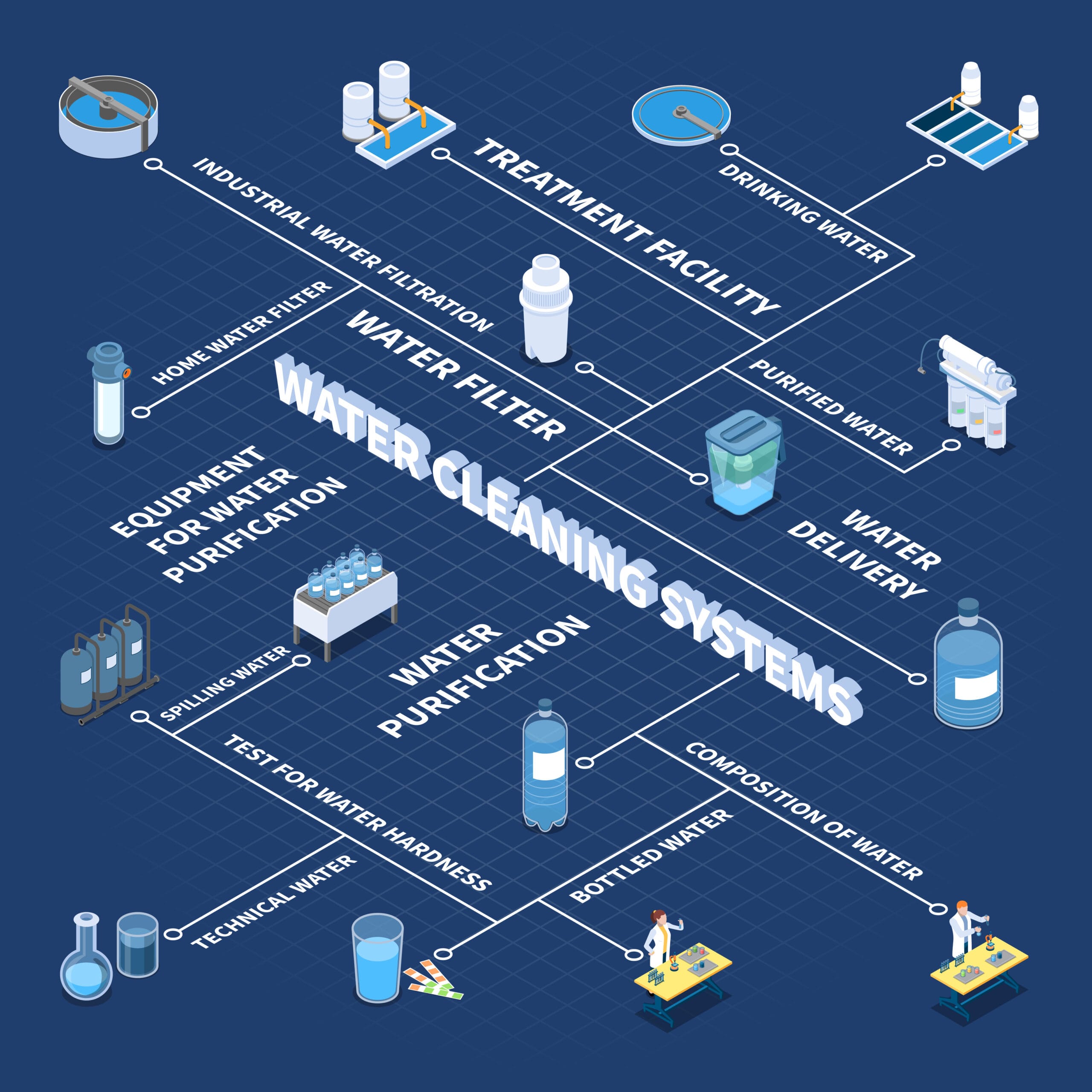

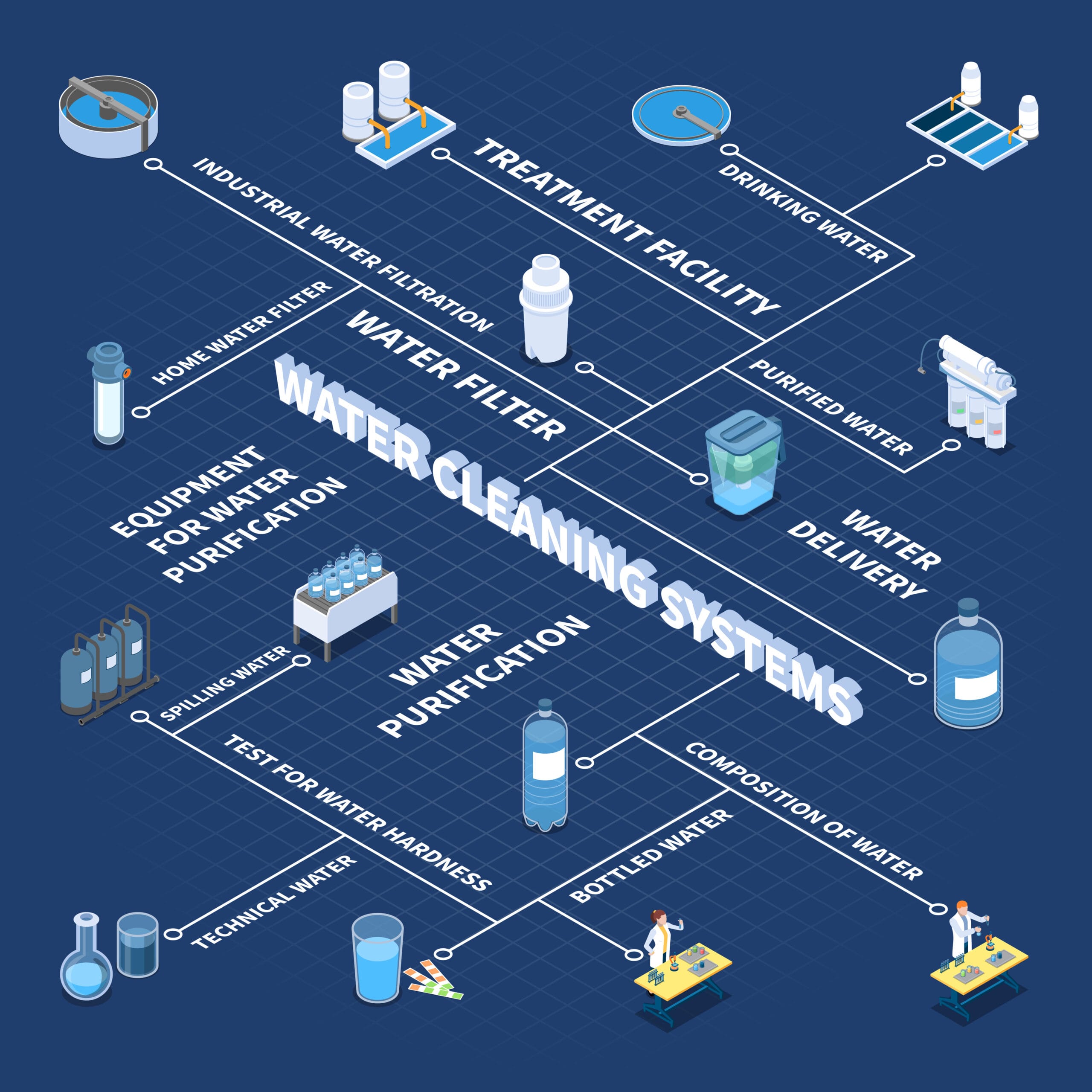

Introduction to Design Qualification of Purified Water Generation Systems

Purified Water Generation Systems: The Design Qualification (DQ) of a Purified Water Generation System plays a crucial role in ensuring that the system meets the required standards for pharmaceutical and biotech processes. This process is essential for providing high-quality water that complies with USP Purified Water Standards and can be used in critical applications such as drug formulation, production processes, and laboratory testing.

The DQ process helps to establish whether the design of the system meets user requirements (URS) and functional specifications (FRS). The ultimate goal is to ensure that the system will reliably produce purified water that adheres to strict quality guidelines. The Design Qualification is performed after the completion of design but before installation or manufacturing of the system.

1. Objective and Scope of Design Qualification Purified Water Generation Systems

1.1 Objective

The objective of DQ is to prepare detailed specifications for all major components of the Purified Water Generation System to ensure that the User Requirement Specifications (URS) and Functional Requirement Specifications (FRS) are achieved. The design must be aligned with the engineering department’s requirements, and the vendor or manufacturer must review these before proceeding to design and manufacture the system.

It also serves as a foundational document for the Validation Activity. Validation, as a later phase in the process, will test whether the system consistently produces purified water that meets the intended specifications.

1.2 Scope

The scope of the Design Qualification encompasses the following:

- New Installations: Implementing a completely new purified water generation system.

- Replacements or Upgrades: When an existing system is replaced or upgraded.

- Modifications: When modifications or enhancements are made to the system.

2. Acceptance Criteria for the Purified Water Generation System

The acceptance criteria ensure that the design complies with the established standards and guarantees the functionality required by the user department and the engineering department. These criteria can be broadly divided into:

2.1 Compliance with Specifications Purified Water Generation Systems

- Water Quality Parameters: The system must ensure that water quality consistently meets the standards outlined in the USP for Purified Water.

- Equipment/Utility Compliance: The equipment and utility systems must conform to the specifications listed in the User Requirements Specification (URS). Certificates of compliance will be issued by the Engineering Department.

2.2 Raw Water Analysis Parameters

To establish a reliable water purification process, certain parameters are typically analyzed for raw water, such as:

- Turbidity: Less than 1.2 NTU (Nephelometric Turbidity Units)

- Total Dissolved Solids (TDS): Typically considered at 120 ppm, considering 20% excess for design.

- pH Level: Should be around 6.9.

- Hardness and Alkalinity: Key parameters that affect the quality of treated water and influence the treatment technology chosen.

These parameters help guide the pretreatment steps like softening and filtration, ensuring that the water entering the purification system is ideal for treatment.

2.3 Pre-Treatment Design Considerations

Pre-treatment serves as the first line of defense in removing undesirable contaminants from raw water before it enters the Reverse Osmosis (RO) System. The design considers:

- Pressure Quartz Filter: The filter removes suspended solids and particulate matter from the water.

- Softening Plant: The softener uses ion exchange resins to remove hardness-causing calcium and magnesium ions, reducing scale formation.

This pretreatment ensures the water entering the Reverse Osmosis (RO) System is relatively clean, maximizing the efficiency and lifespan of subsequent treatment steps.

3. System Description

The Purified Water Generation System is composed of several stages of treatment that work together to meet the required water quality standards:

3.1 Reverse Osmosis (RO) System

The RO System is central to producing purified water:

- RO Pass I and II: These two stages of reverse osmosis remove dissolved solids and other impurities from the feed water. The first pass typically has a recovery rate of 70-75%, and the second pass improves the recovery rate to 80-85%.

- Post-RO Treatment (EDI & UF): After the RO system, Electro Deionization (EDI) and Ultrafiltration (UF) membranes ensure that the water meets stringent quality parameters:

- EDI: Removes ions and maintains ultra-low levels of conductivity (less than 0.5 µs/cm²) and low Total Organic Carbon (TOC), in line with USP requirements.

- UF: Provides further filtration to reduce TOC and bacterial count, ensuring that the water quality is consistently high.

3.2 Instrumentation and Controls

The system is equipped with:

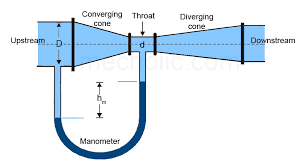

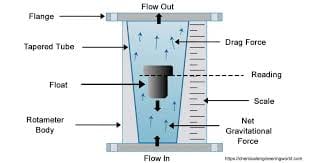

- Conductivity Meters to monitor the purity of water at different stages of the treatment process.

- ORP (Oxidation-Reduction Potential) Sensors to check for chlorine presence in the water, ensuring that the RO membranes are protected from damage.

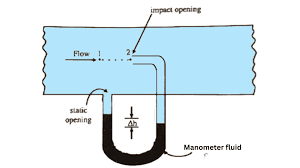

- Flow Meters to measure the flow rates at different points and ensure that each stage operates optimally.

The PLC-based automation allows for seamless operation and monitoring, triggering alarms and shutdowns when necessary.

4. Basis of Design and Assumptions

The design of the system is based on specific assumptions regarding the raw water quality (referencing the provided Annexure A) and the expected output.

4.1 Design Assumptions:

- The system is designed for continuous operation, with an average daily flow rate of 200 liters per hour of purified water.

- System Capacity: Based on the raw water quality, the system is designed to process water at an intake rate of 32 m³/hr through the pre-treatment units.

- Recovery Rates: Recovery rates for RO and EDI stages are set to be between 70% and 85%, ensuring that the water generated meets required purity levels.

4.2 Design Basis for Water Quality

The treated water quality is evaluated on several key factors:

- Conductivity: The conductivity at the outlet of the EDI unit must be below 0.5 µs/cm², which is well within the USP’s acceptable limit for Purified Water.

- Bacterial Count: The total bacterial count must be less than 50 CFU/mL (colony-forming units), ensuring the water is free from microbiological contamination.

- TOC Levels: Total Organic Carbon is closely monitored, with stringent limits of 200 ppb in purified water.

These parameters ensure that the water is of the highest quality for use in pharmaceutical manufacturing and testing.

5. Technical Specifications

5.1 Key Equipment Specifications:

- Raw Water Pump: A centrifugal monobloc pump with a flow rate of 32 m³/hr is used for feeding the water into the system.

- Reverse Osmosis Membranes: High-performance polyamide thin-film composite membranes with a molecular weight cut-off of 150 Da are used for the RO Pass I and II stages, ensuring maximum filtration efficiency.

- Electro Deionization (EDI) Units: These are used to polish the water to ultra-pure levels, removing any remaining ions that may affect the quality.

The system is also designed with provisions for periodic sanitization, maintenance, and performance checks.

6. Calibration and Testing

All critical components of the water generation system, including conductivity meters, pressure gauges, flow meters, and ORP sensors, must undergo thorough calibration to ensure they are accurate and reliable. Calibration is performed according to the manufacturer’s guidelines, and regular verification ensures continued performance.

7. Supporting Utilities and Infrastructure

A well-designed purified water system requires various supporting utilities to operate effectively:

- Water Supply: The system requires a stable raw water supply at the right pressure and flow rate.

- Electric Power: The system operates on three-phase 440V, 50Hz power, essential for the pumps and control systems.

- Compressed Air: Certain dosing systems require compressed air for operation.

Conclusion:

The Design Qualification of the Purified Water Generation System is a critical phase in ensuring that the system will meet the stringent standards of USP Purified Water. The process focuses on every aspect of the system, from pretreatment to post-treatment, ensuring that each component works together to achieve the desired water quality. Through comprehensive design documentation, validation activities, and regular checks, the system is guaranteed to produce high-quality purified water that meets pharmaceutical standards for both safety and efficacy.

Leave a Reply